INDUSTRY NEWS

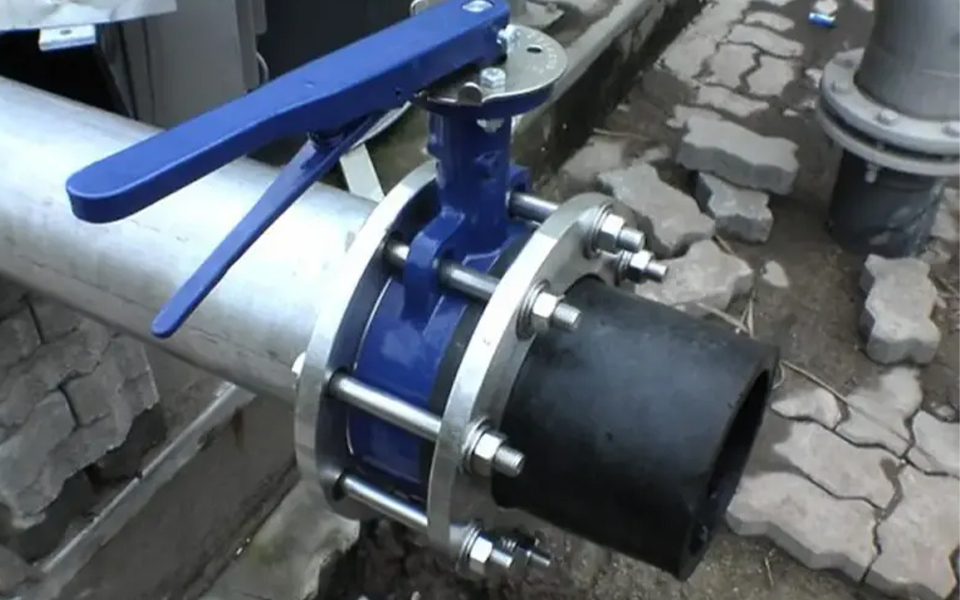

Valve installation Tutorial How to avoid leakage and loosening

Valves play a vital role in a fluid system, and proper valve installation is critical to ensure proper system operation and safety. Leakage and loosening are common problems during valve installation

1. Preparation before installation

Select the right valve: According to the requirements of the fluid system, select the right valve type and specification. Consider the nature of the fluid, temperature, pressure and other factors to ensure that the valve can meet the needs of the system, and has good sealing performance.

Check the valve: Before installation, perform a comprehensive inspection of the valve. Make sure there are no damaged, defective or leaking valves. At the same time, check the sealing surface and connection parts of the valve to ensure that they are intact.

Preparing tools and materials: Prepare required installation tools and materials, such as wrenches, screwdrivers, gaskets, and sealants. Ensure the quality and suitability of these tools and materials, and pay special attention to the selection of suitable gaskets and sealants.

2. Installation steps

Determine the installation location: Determine the installation location of the valve according to the layout and design requirements of the fluid system. Ensure that valves are easy to operate and maintain, and comply with the system's process flow.

Clean interfaces: Thoroughly clean pipe interfaces and valve connections before installing valves. Use appropriate cleaners and tools to remove impurities, oil and rust, and ensure that the interface is clean and smooth.

Install the valve: Place the valve in the desired position and use the appropriate tools to connect the valve to the pipe. During the connection process, ensure that the alignment of the valve with the pipe is accurate to avoid excessive stress or distortion. Use the appropriate torque and tightening sequence to ensure that the connection is securely fastened to avoid leakage and loosening.

Check the sealing performance: After the installation is complete, the sealing performance of the valve is comprehensively checked. When the valve is closed, check whether there is leakage at the connection between the valve and the pipeline. If a leak is found, the cause should be found in time and appropriate remedial measures should be taken, such as replacing the gasket or readjust the connection part.

Precautions to avoid leakage and loosening

Select the right gasket: According to the requirements of the fluid system, select the appropriate gasket material and specifications. Ensure that the gasket has good corrosion resistance, high temperature resistance and sealing performance. During the installation process, install the gasket correctly and ensure that it is in the correct position and not damaged.

Use appropriate torque: When connecting valves and pipes, use appropriate torque for tightening. Avoid excessive force or use of excessive torque, so as not to damage the valve or pipe connection. Tighten the valve and pipe with the appropriate tools according to the specifications and materials, referring to the tightening torque requirements provided by the manufacturer.

Regular inspection and maintenance: After installation, check and maintain the valve and connecting parts regularly. Check whether the gasket is aged or damaged, and whether the connection part is loose or leaking. If a problem is found, replace the gasket or re-tighten the connection part in time to ensure the tightness and stability of the valve.