INDUSTRY NEWS

There are several connection methods for butterfly valves

Butterfly valves are a common type of control valve and are widely used in various industrial fields. When installing butterfly valves, the connection method is a very crucial link.

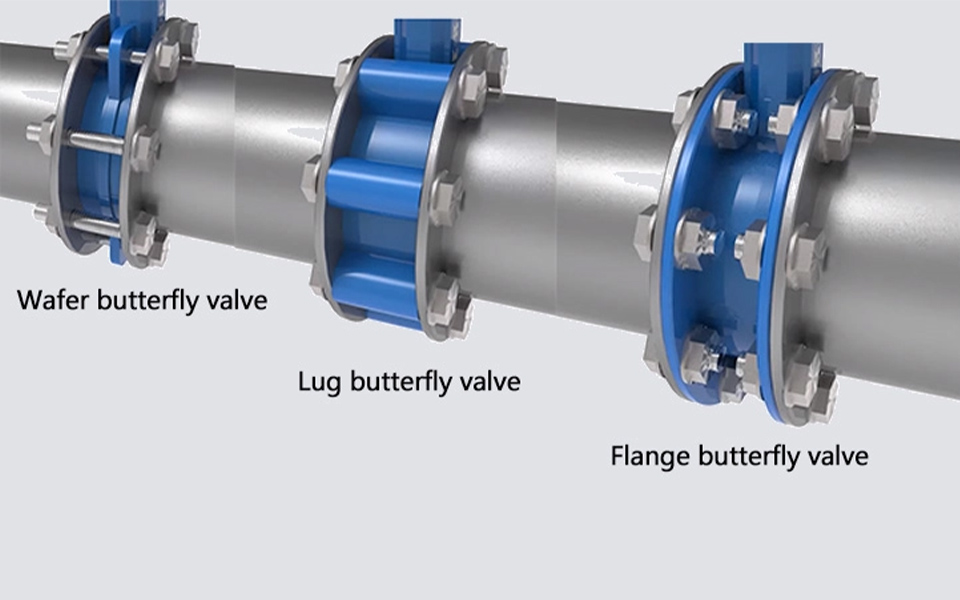

I. Types of Connection Methods for Butterfly Valves

1. Flange connection

Flange connection is one of the most common connection methods for butterfly valves. Flange connections are divided into two types: flat flanges and flange flanges. The connection method of both is to tightly fix the butterfly valve and the pipe flange together through bolts. Flange connections have the characteristics of strong connection fastening force, easy installation and disassembly, and high reliability.

2. Threaded connection

Threaded connection is another way to connect a butterfly valve to a pipeline. Threaded connections are divided into two types: internal threads and external threads. Internal thread connections are suitable for connecting butterfly valves with pipe fittings on the inner side of the pipeline, while external thread connections are suitable for connecting butterfly valves with pipe fittings on the outer side of the pipeline. Threaded connections have the characteristics of simple connection and reliable fastening.

3. Welding connection

Welding connection is a connection method that welds the butterfly valve to the pipeline together. Welding connections are divided into two types: butt welding connections and embedded welding connections. Butt welding connections are suitable for connecting butterfly valves with pipe fittings on the outside of pipelines, while embedded welding connections are suitable for connecting butterfly valves with pipe fittings on the inside of pipelines. Welded connections have the characteristics of strong connection fastening force and reliable sealing.

Ii. Characteristics of Butterfly Valve Connection Methods

1. Characteristics of flange connection

The characteristics of flange connection are strong connection fastening force and high sealing reliability between the butterfly valve and the pipeline. In addition, flange connections also feature easy installation and disassembly, which can reduce downtime and enhance production efficiency.

2. Characteristics of threaded connections

The feature of threaded connection is that it is simple to connect and does not require additional fasteners, so it is relatively convenient to install. In addition, threaded connections also have the characteristics of strong connection fastening force, which can ensure the firmness of the connection.

3. Characteristics of welded connections

The characteristics of welded connection are strong connection fastening force and good sealing performance between the butterfly valve and the pipeline. In addition, welded connections also feature compact connections and no additional connectors, which can reduce the possibility of leakage.

Iii. Applicable scope of Butterfly Valve Connection Methods

1. The applicable scope of flange connection

Flange connections are suitable for large-diameter and high-pressure pipeline systems. When connecting, flange connections require a large number of bolts for fastening, so the connection reliability is high and it is suitable for occasions with strict requirements.

2. The applicable scope of threaded connections

Threaded connections are suitable for small-diameter and low-pressure pipeline systems. When connecting, the threaded connection only requires the butterfly valve and the pipeline to be tightly fixed together with the thread. The connection is simple and convenient, and is suitable for occasions where frequent disassembly and replacement are needed.

3. The applicable scope of welded connections

Welding connections are suitable for pipeline systems in special environments such as high temperature, high pressure, flammability and explosiveness. When connecting, the welding connection directly welds the butterfly valve to the pipeline. It has a strong connection fastening force and is suitable for occasions with high connection requirements.