INDUSTRY NEWS

The working conditions applicable to butterfly valves

There are many types of butterfly valves, including those for quick shut-off and those for continuous regulation. It is mainly used for low-pressure large-diameter pipelines of liquids and gases. It is suitable for occasions where the requirement for pressure loss is not high, flow regulation is needed, and quick opening and closing are required. Generally, in situations where the temperature is below 300℃ and the pressure is below 40 kilograms, the medium is usually water and gas. The requirements for the medium are not high, and granular media can also be used.

As a sealed butterfly valve, it has developed rapidly only after the emergence of synthetic rubber. Therefore, it is a new type of shut-off valve. Butterfly valves can convey and control media such as water, condensate water, circulating water, sewage, seawater, air, gas, liquid natural gas, dry powder, slurry, fruit pulp and mixtures with suspended solids.

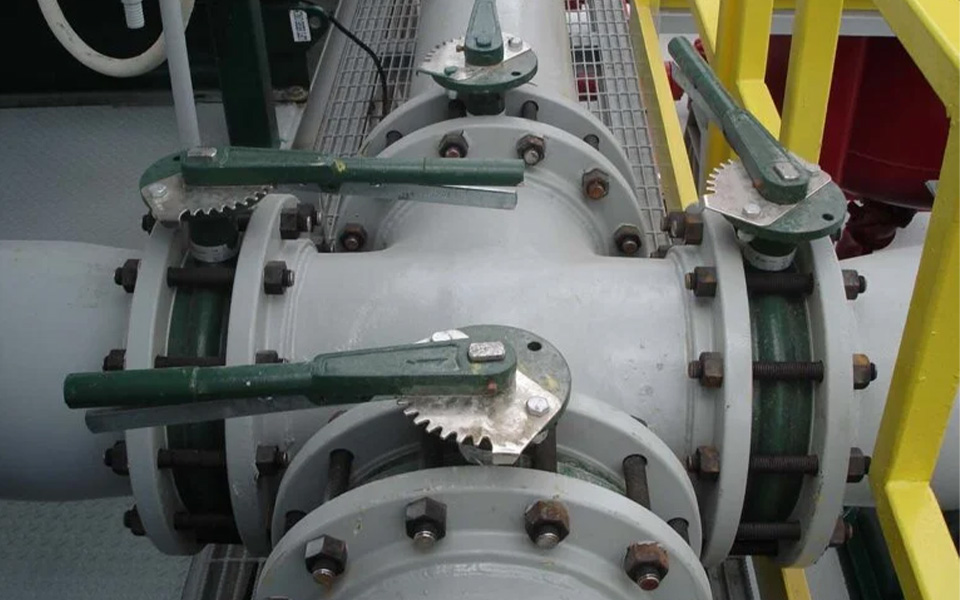

Butterfly valves are suitable for flow regulation. Due to the relatively large pressure loss of butterfly valves in pipelines, which is approximately three times that of gate valves, when choosing butterfly valves, the impact of pressure loss on the pipeline system should be fully considered. Additionally, the robustness of the butterfly plate in withstanding the pressure of the pipeline medium when closed should also be taken into account. In addition, the limitation of the working temperature that the elastic valve seat material can withstand at high temperatures must also be taken into consideration. Butterfly valves have a relatively small structural length and overall height, open and close quickly, and possess excellent fluid control characteristics. The structural principle of butterfly valves is suitable for manufacturing large-diameter valves. When butterfly valves are required to be used for flow control, it is important to correctly select the size and type of the butterfly valve so that it can work appropriately and effectively.

Generally, in throttling, regulating control and slurry media, a short structural length and a fast opening and closing speed (1/4 turn) are required. For low-pressure cut-off (small pressure difference), it is recommended to use a butterfly valve.

Butterfly valves can be selected when there are two-position regulation, constricted channels, low noise, cavitation and vaporization phenomena, slight leakage to the atmosphere, and abrasive media.

When using butterfly valves under special working conditions such as throttling regulation, strict sealing requirements, severe wear, and low-temperature (cryogenic) conditions, it is necessary to use specially designed metal-sealed butterfly valves with regulating devices that are either three-eccentric or double-eccentric.

Wafer butterfly valves are suitable for applications that require complete sealing, zero leakage in gas tests, high service life, and operating temperatures ranging from -10℃ to 150℃, including fresh water, sewage, seawater, brine, steam, natural gas, food, medicine, oil products, and various acids, alkalis, and other pipelines.

Resilient eccentric butterfly valves are suitable for bidirectional opening, closing and regulation of ventilation and dust removal pipelines, and are widely used in gas pipelines and waterways of metallurgy, light industry, power, petrochemical systems, etc.

The metal-to-Mental seat double eccentric butterfly valve is suitable for pipelines of gas, oil, acid and alkali in urban heating, gas supply, water supply, etc., and is used as a regulating and throttling device.

Metal-to-mental seat triple eccentric butterfly valves, in addition to being used as program control valves in large-scale pressure swing adsorption (PSA) gas separation units, can also be widely applied in fields such as petroleum, petrochemical, chemical engineering, metallurgy, and power. They are excellent alternative products to gate valves and globe valves.