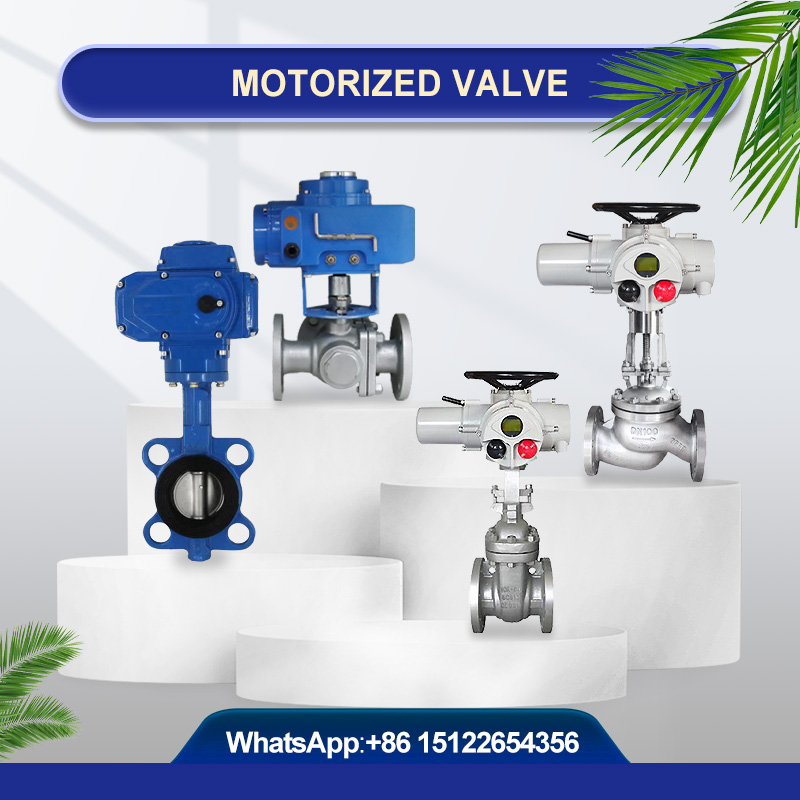

Products

Factory Direct Motorized Actuator Valves Quality Supply Control Valves

Electric actuator control valves have a number of advantages when use in industrial applications. First, they can provide precise control over fluid flow, allowing operators to accurately adjust the flow rate with minimal effort. This makes them ideal for processes that require precision or modulation of flow. Additionally, electric actuator control valve respond quickly and reliably to electrical signals, making them suitable for automate processes as well.

What about the motorized valve?

The Motorized valve can be called electric valve, mov valve, motor valve, etc.. The operation and control of the motorized valve is realized by the motorized device, which can accurately and reliably control the flow, pressure and temperature parameters of the working medium. The opening and closing operation of the electric valve is responsible for the driving part, and the electric control part is responsible for controlling the opening size and adjusting the dynamic performance of the valve to achieve automatic control.

We are a motorized valve manufacturer specializing in motor actuator valve. The quality of our motor driven valves is consistent and reliable.

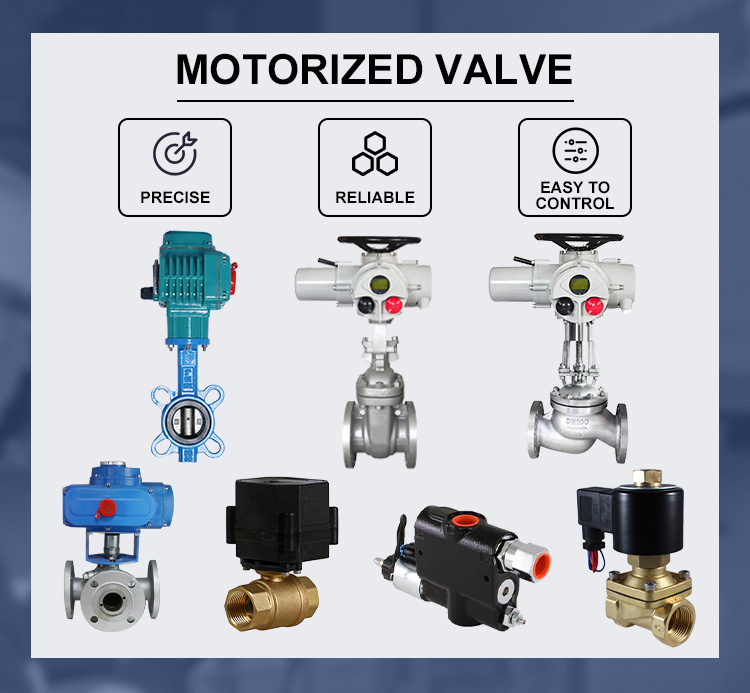

1.Quick response

One of the advantages of electric valves is that they respond quickly, allowing for more precise control and operation. In situations where rapid response is required, electric valves can greatly improve production efficiency and safety.

2.Precise control

Another advantage of electric valves is precise control. In addition, the electric valve can also realize automatic control and operate according to preset parameters, reducing labor costs and improving production efficiency.

3. High reliability

The third advantage of electric valves is high reliability. The electric valve is driven by electricity, which can avoid human error caused by manual operation, and can also realize real-time monitoring and remote control of the status of the valve.

4. Wide range of application

The application range of electric valves is very wide and can be used in various industries and fields. For example, electricity, chemical, petroleum, water treatment, pharmaceutical and so on.

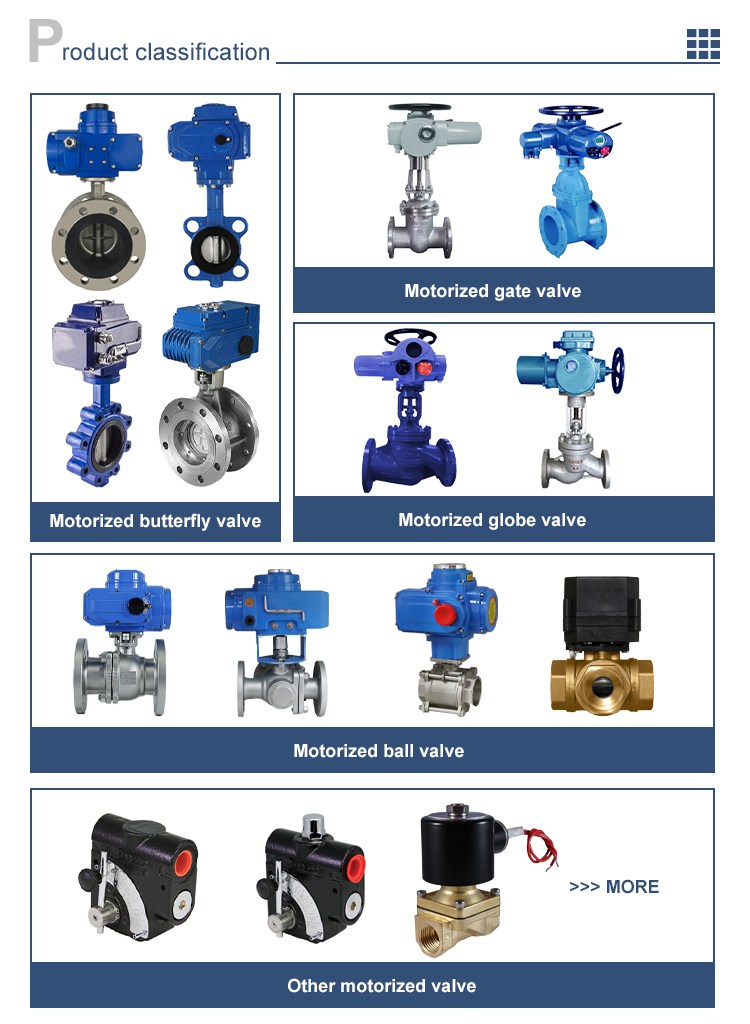

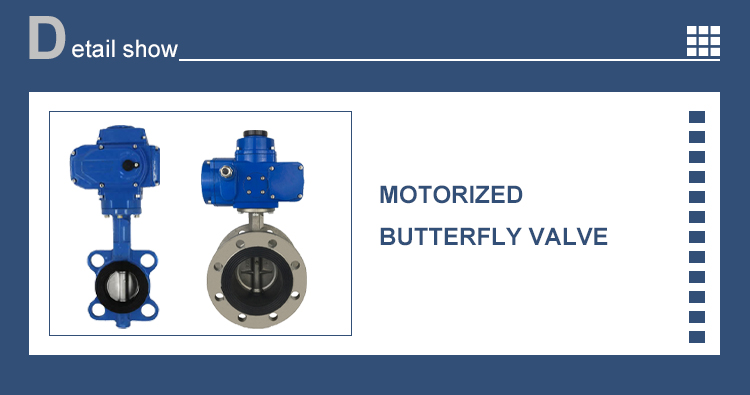

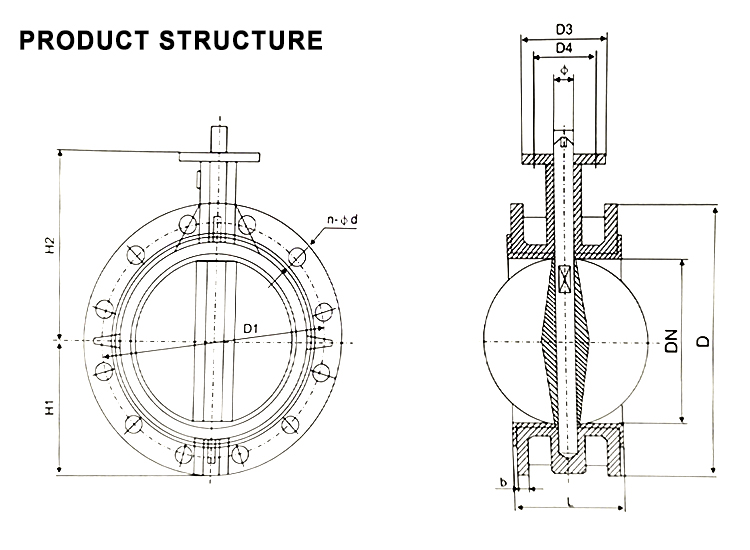

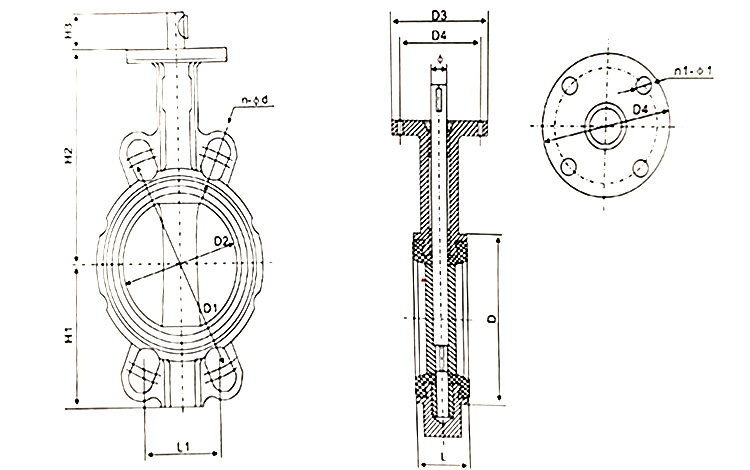

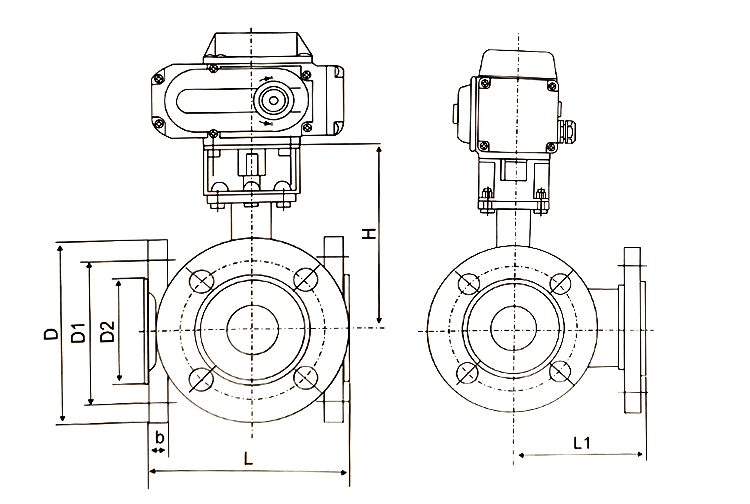

MOTORIZED FLANGE BUTTERFLY VALVE

MOTORIZED WAFER BUTTERFLY VALVE

|

Optional function of electric actuator |

Switching type, regulating type, intelligent body type |

|

Voltage |

AC220V,AC110V,AC380,DC12V,DC24V,DC110V |

|

Nominal diameter |

DN25mm~DN1400mm |

|

Nominal pressure |

PN1.0Mpa~PN1.6Mpa |

|

Applicable temperature |

EPDM:-30~+100℃ PTFE:-30~+120℃ |

|

Connection mode |

Wafer |

|

Valve body material |

Ductile ink, carbon steel, stainless steel |

|

Valve disc material |

Spherical ink, 304, 316, 316L, 2507, 1.4529, copper plate, nylon, etc |

|

Valve seat lining |

NBR、EPDM、PTFE |

|

Applicable medium |

Water, gas, slurry, oil, etc |

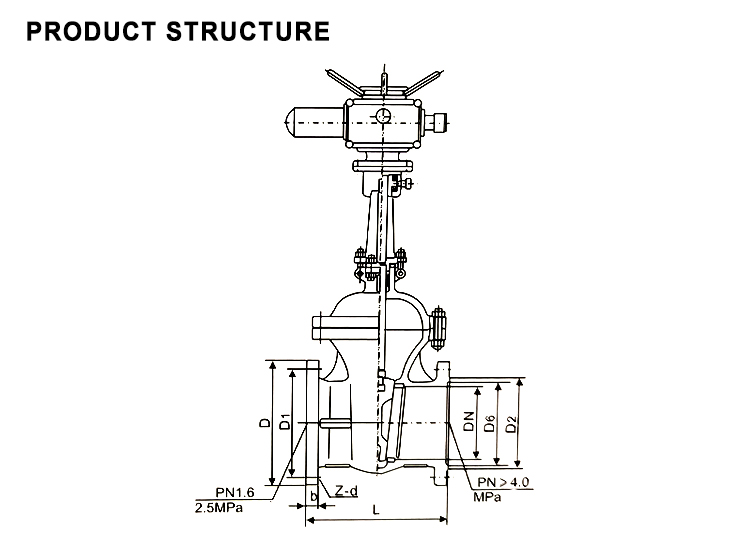

MOTORIZED GATE VALVE

|

Optional function of electric actuator |

Switching type, regulating type, intelligent body type |

|

Voltage |

AC220V AC380 |

|

Nominal diameter |

DN40mm~DN1000mm |

|

Nominal pressure |

PN1.0Mpa~PN6.4Mpa |

|

Applicable temperature |

-30~+550℃ |

|

Connection mode |

Flange type |

|

Valve body material |

Cast steel, stainless steel |

|

Valve disc material |

Cast steel, stainless steel |

|

Valve seat lining |

PPL, body material |

|

Applicable medium |

Water, oil, steam, acid, alkali, ammonia, urea, sulfur-containing natural gas, etc |

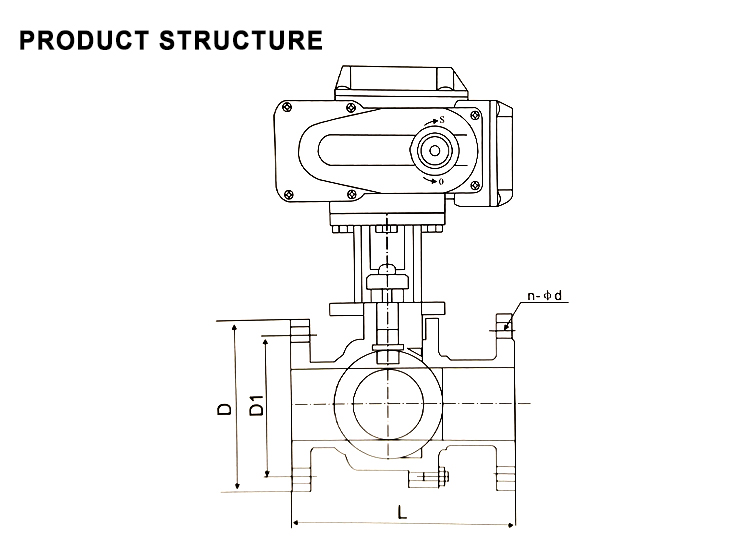

MOTORIZED FLANGE BALL VALVE

MOTORRIZED THREE WAY VALVE

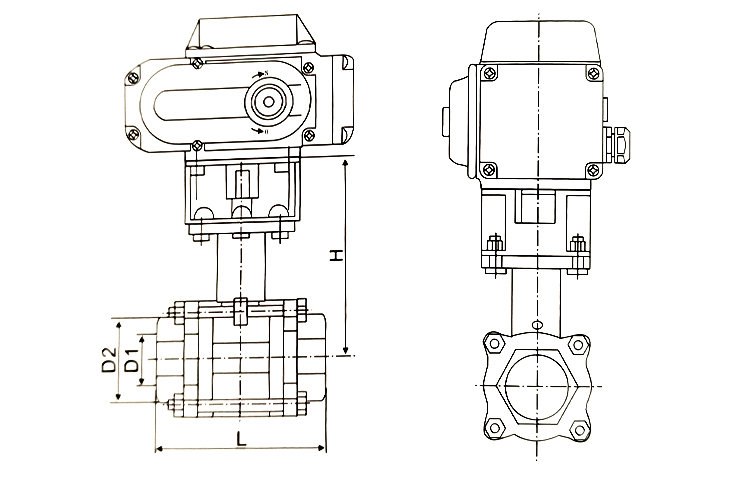

MOTORIZED WIRE BALL VALVE

|

Optional function of electric actuator |

Switching type, regulating type, intelligent body type |

|

Voltage |

AC220V,AC110V,AC380,DC12V,DC24V,DC110V |

|

Nominal diameter |

DN15mm~DN200mm |

|

Nominal pressure |

PN1.0Mpa~PN1.6Mpa |

|

Applicable temperature |

PTFE: -30~+120℃ PPL:≤350℃ Metal seal :≤ 450℃ |

|

Connection mode |

Flange type |

|

Valve body material |

304, 316, 316L |

|

Valve disc material |

304、316、316L |

|

Valve seat lining |

Cast steel, 304, 316, 316L |

|

Applicable medium |

Water, petroleum, acids, viscous fluids, slurry media, etc |

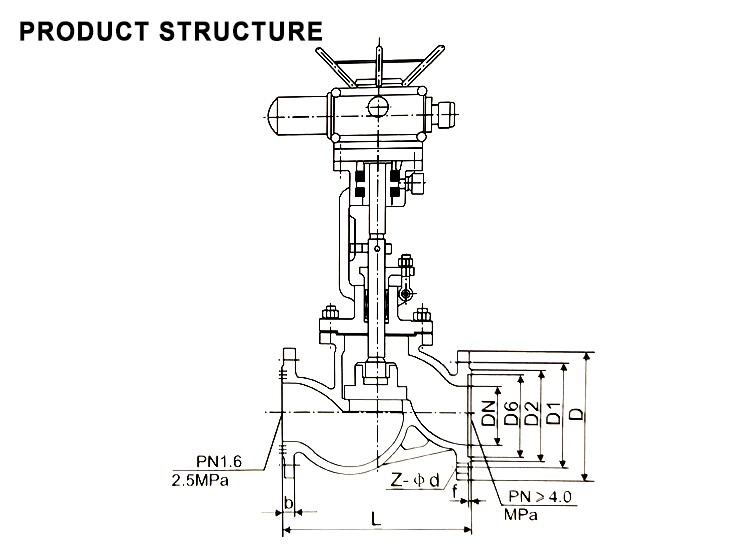

MOTORIZED GLOBE VALVE

|

Optional function of electric actuator |

Switching type, regulating type, intelligent body type |

|

Voltage |

AC220V AC380 |

|

Nominal diameter |

DN40mm~DN300mm |

|

Nominal pressure |

PN1.0Mpa~PN6.4Mpa |

|

Applicable temperature |

-30~+550℃ |

|

Connection mode |

Flange type |

|

Valve body material |

Cast steel, stainless steel |

|

Valve disc material |

Cast steel, stainless steel |

|

Valve seat lining |

PPL, body material |

|

Applicable medium |

Water, oil, steam, etc |

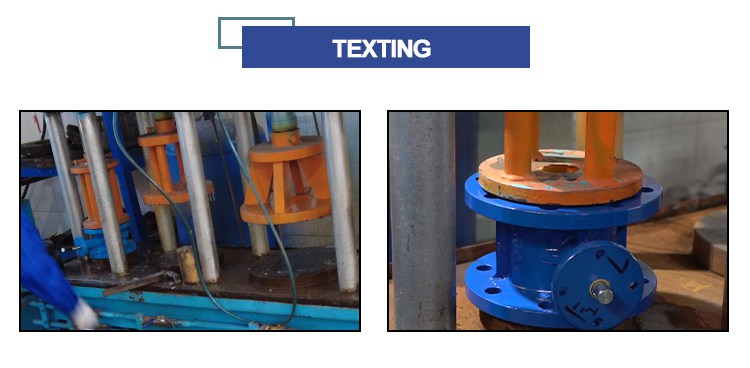

Each valve shall be subject to pressure test before delivery. Unqualified valves shall not be sold.16 kg shell pressure test, pressure test pressure 24 kg; Maintain the pressure for 2 minutes; Sealing pressure test: test pressure 17.6 kg; Hold the pressure for 2 minutes.

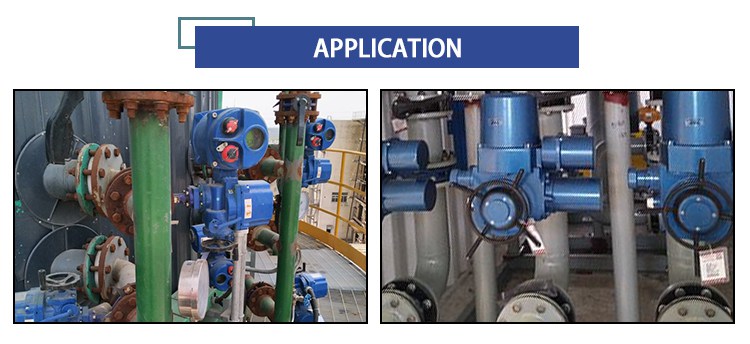

Electric valves have a wide range of applications, common uses include the following:

1. Fluid control in air conditioning systems and HVAC systems

The electric valve can control the flow of water, steam, oil and other fluid media in the indoor air conditioning and HVAC system, adjust the ambient temperature and humidity, achieve automatic control, and provide a comfortable indoor environment.

2. Fluid control in engineering and manufacturing

Electric valves are also widely used in the field of chemical and manufacturing fluid control, such as petrochemical, electric power, metallurgy, shipbuilding, paper, food and other industries, in the production process to regulate the flow, pressure, temperature and other roles.

3. Sewage treatment and environmental protection

In the field of sewage treatment and environmental protection, electric valves can effectively control the operation of sewage treatment equipment and improve the efficiency and operational stability of sewage treatment.

As a professional electric valve supplier, we sincerely look forward to your consultation and cooperation.